Multi-layer shims from MARTIN optimize the adjustment of the preload

Roller bearing manufacturers have always invested a considerable amount of time and effort in developing ways to increase the service life of their products. It is of particular importance for the longevity and performance of tapered roller bearings and angular contact ball bearings that the axial preload is set in the ideal way during assembly.

This is achieved with almost playful ease thanks to the precision shims in MARTIN’s Laminum® and Lamivario® line. When roller bearing professionals, transmission manufacturers and drive technicians exchange their know-how, there will also be plenty of focus on how to achieve the ideal preload and precise adjustment of axial play when installing roller bearings in drive technology modules.

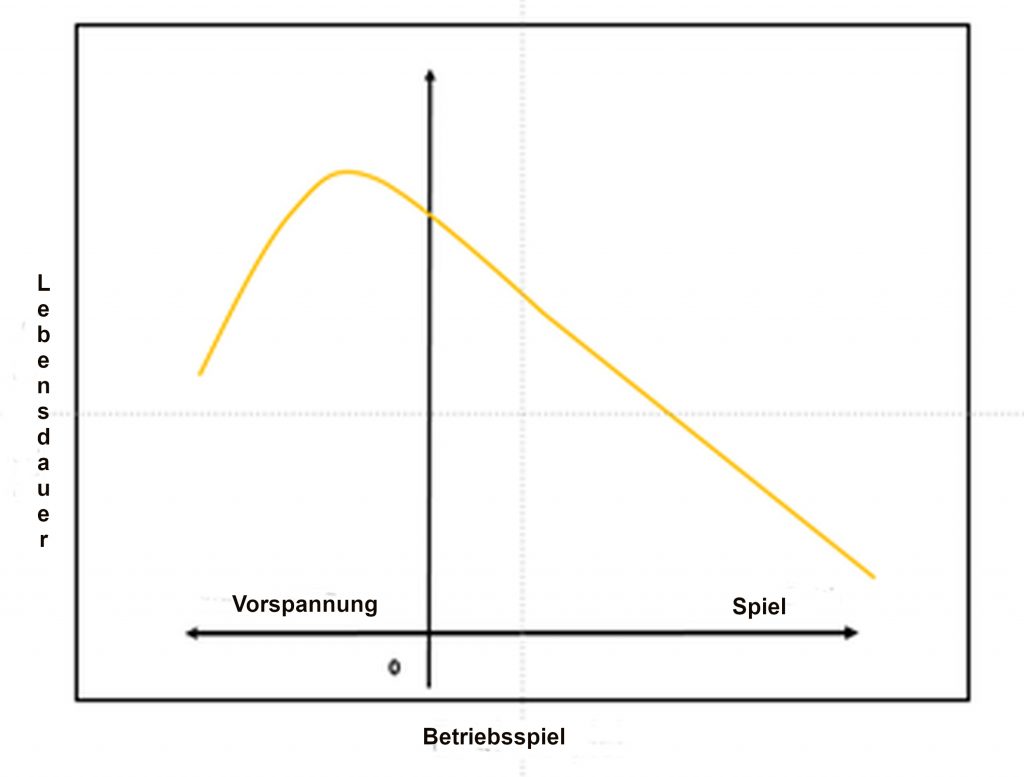

The reason for this is that with several roller bearing types, this process is decisive – as a construction stage as well as during maintenance and assembly work – for the efficiency and service life of the bearings. In actual practice, the adjustment of axial bearing play is of vital importance, especially when installing single and double-row angular contact bearings, four-point contact bearings and single and double-row tapered roller bearings. It has a direct influence on the achievable downtime, vibration behaviour and noise and heat development of a roller bearing application.

As a long-serving supplier and project partner to many renowned transmission manufacturers and plant engineering specialists, MARTIN offers its know-how here in the form of highly specialized shims. “To advance the development of our products and promote mutual inspiration, we seek a constant exchange with the manufacturers and users of roller bearings. An event like the new online trade fair Bearing Application World is therefore of great benefit to us, as we can make contact with manufacturers as well as users,” explains CEO Christoph Martin. His company is one of the premium manufacturers of shims with which users can adjust the presetting and thereby optimize the preload of the roller bearings precisely to within 5.0 micrometres. In practice, this is achieved using multi-layer adjustment elements of the Laminum® and Lamivario®line with their thin, peelable layers. In this way, users can easily reach a required precision of one or two tenths of a millimetre without any machining and without having to keep a supply of graduated washers of different thicknesses. The use of shims from MARTIN enables constructors and fitters to compensate the total tolerance of the components in a simple manner and realize the correct degree of preloading almost perfectly. In theory, therefore, the service life of the roller bearings calculated by the manufacturer can be achieved to a great extent.

Regarding the question of how to achieve optimum roller bearing performance in actual practice under specific operating conditions, not all users make full use of the given optimization potential, preferring instead to calculate a kind of ‘safety margin’ in advance. “They are often faced with a dilemma,“ says Professor Dr. Stephan Sommer of the Laboratory for Quality Management, Production and Roller Bearing Technology at the University of Applied Sciences Würzburg-Schweinfurt, and explains further: “Getting close to the optimum preload extends the service life of the roller bearing. If you exceed the optimum, however, the service life curve drops sharply and premature failure results. In light of this balancing act, some constructors and fitters prefer to play it safe and opt for clearance that is greater than necessary, which can reduce service life by up to 20 percent, even though the roller bearing manufacturers optimize their products right down to the last detail. The safety margin can grow to up to two tenths, especially as many users also take other influencing factors, such as thermally induced material expansion, into account”.

Exact preloading instead of a safety margin

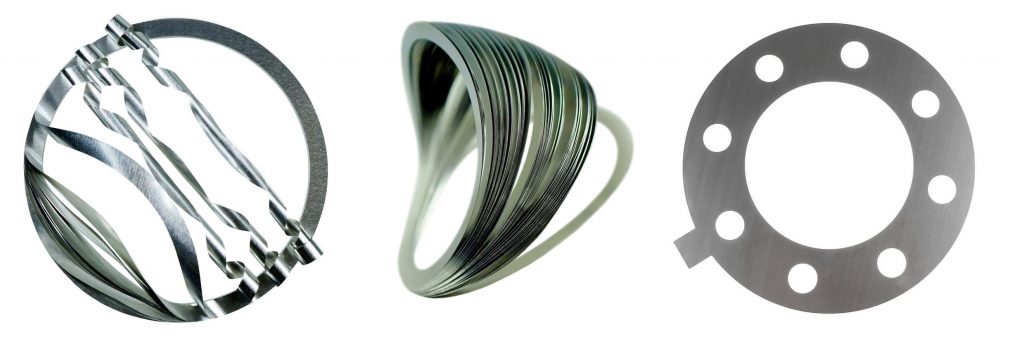

With their shims in the Laminum® or Lamivario® line, which are usually manufactured in compliance with customers’ drawings, MARTIN offers roller bearing users a way out of their dilemma which is as simple as it is precise. Produced in series, these adjustment shims consist of multiple wafer-thin, laminated or edge-welded metal films made of steel, stainless steel, aluminium plastic and brass. In this way, the thickness of the adjustment ring can be reduced as required by stripping or peeling. The typical film thicknesses range from 5.0 micrometres to two tenths of a millimetre.

MARTIN is also making users aware of the enormous potential of process optimization which can be realized through the systematic use of Laminum® and Lamivario® elements. If the OEM constructor already integrates the multi-layer shims into his or her drawings, the amount of time, money and effort required by the customer in all upstream and downstream processes, from purchasing through assembly to maintenance, are also reduced. “If this is additionally combined with the list of components in accordance with requirements – roughly in line with the principle ‘the right shim per se for every joint’ – roller bearing assembly makes a huge leap in efficiency,” explains Christoph Martin.

And as the necessity for machining can be done away with completely, the use of processing machinery becomes completely obsolete, including the related location and shortest path problems, waiting times, rejection rates and personnel issues.

Task-specific individualization

At their virtual fair booth at the Bearing Application World 2021 MARTIN will also be pointing out the opportunities for process optimization that arise through the task-specific individualization of the Laminum® and Lamivario® shims. The thicknesses as well as the materials used for the strip-off or peelable films can be coordinated for each individual project to suit almost all scenarios involving the adjustment of axial play during the assembly of roller bearings. “We can customize the composite films in such a way that their configuration suits each assembly process and one single multi-layer shim covers all alignment tasks. “Lots of our customers who install roller bearings have recognized this and use our Laminum® and Lamivario® elements to satisfy LEAN requirements,” comments Christoph Martin. In cases of this kind there is also less work for purchasing staff, as they no longer have to procure dozens of different compensation elements.

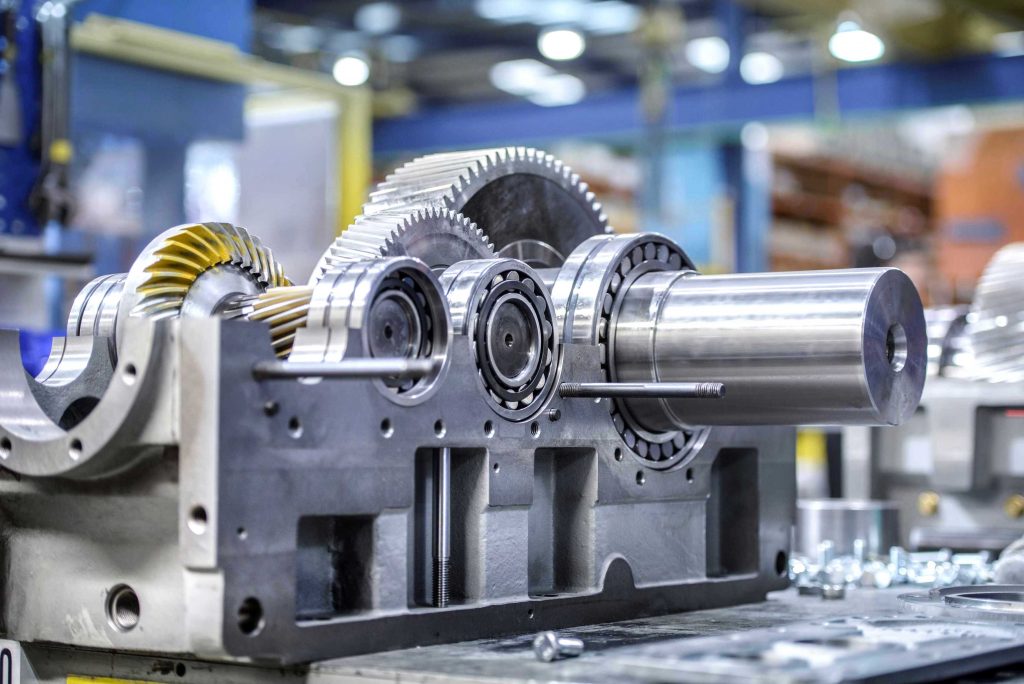

Fundamentally, it is always the specific application that decides if or which shims are the suitable means of compensating the axial play of roller bearings. Whereas flexible compensation elements are better suited for applications such as high-speed rotations with an increased vibration tendency, shims prove to be ideal in applications with high demands on bearing rigidity, such as the mounting of shafts in transmissions, pumps, mining machinery and conveyor system.

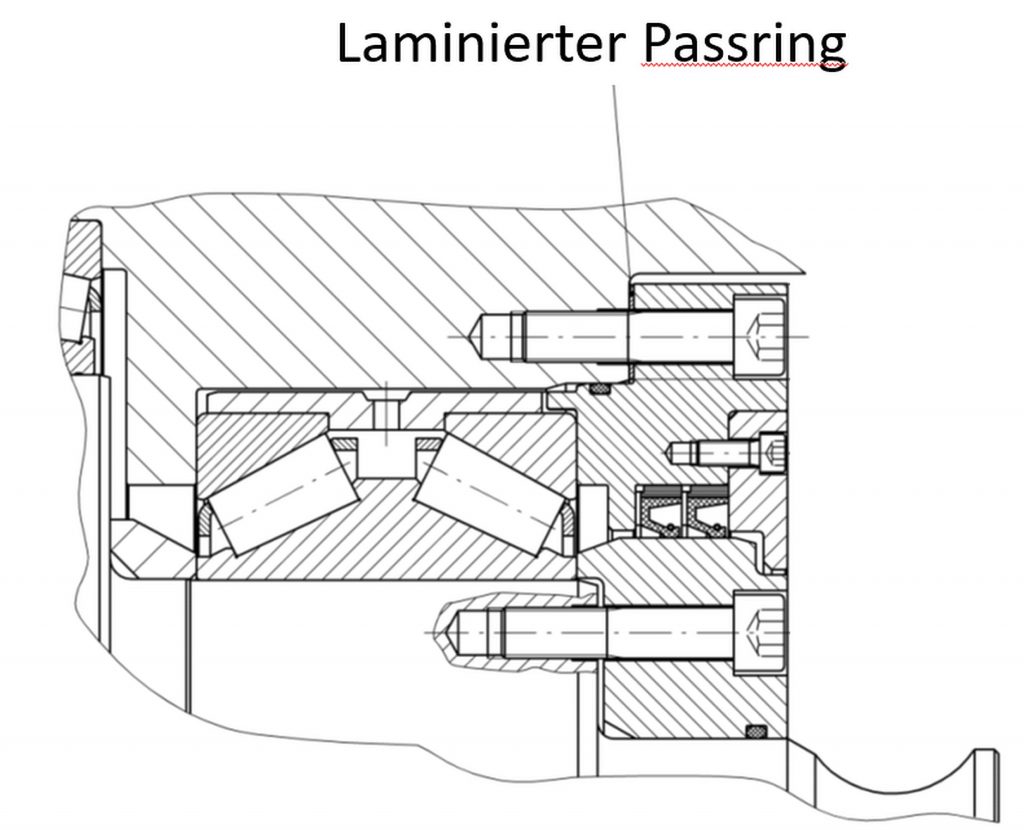

The installation position of the fitting element also has to be considered. “The question of the installation point of the shims should be clarified during the construction phase. The quasi-static installation situation – roughly between the housing and the cover – is ideal when using Laminum® and Lamivario® fitting elements, where the cover produces the preload via a flange on the roller bearing outer ring,“ adds Christoph Martin.

By the way: In its Lamisol® line, MARTIN also offers all conventional types of solid fitting elements for all cases where the use of Laminum® and Lamivario® shims is not possible.